Ultimate Guide: Design Your Bore With Expertise

Bore design is an intricate process that requires precision and a deep understanding of various factors. Whether you're an experienced designer or a beginner, this comprehensive guide will walk you through the steps to create a bore that meets your specific needs and ensures optimal performance. From understanding the basics to implementing advanced techniques, we'll cover it all. Let's dive in and explore the world of bore design!

Understanding the Basics of Bore Design

Before we delve into the intricacies of bore design, it's essential to grasp the fundamental concepts. A bore, in simple terms, is a cylindrical hole or cavity that serves a specific purpose in various applications. It can be found in engines, firearms, drilling equipment, and many other mechanical systems.

The design of a bore plays a crucial role in determining its functionality and performance. It involves careful consideration of factors such as diameter, depth, surface finish, and material selection. By understanding these basics, you can lay a strong foundation for creating a well-designed bore.

Key Considerations in Bore Design

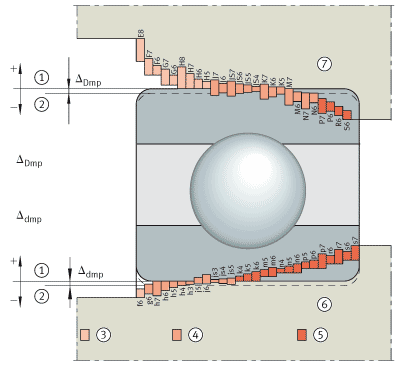

- Diameter and Depth: The diameter and depth of a bore are critical parameters that influence its overall dimensions and the amount of material it can accommodate. These factors are determined by the intended application and the specific requirements of the system.

- Surface Finish: The surface finish of a bore is crucial for ensuring smooth operation and reducing friction. It can be achieved through various techniques such as honing, grinding, or polishing, depending on the desired level of precision.

- Material Selection: Choosing the right material for your bore is essential for its durability and performance. Factors like strength, corrosion resistance, and thermal conductivity should be considered when selecting the material.

Selecting the Right Tools for Bore Design

To design a bore effectively, you'll need a set of specialized tools and software. These tools enable you to create accurate models, simulate real-world conditions, and optimize your design for maximum performance.

CAD Software for Bore Design

Computer-Aided Design (CAD) software is an indispensable tool for bore design. It allows you to create detailed 2D and 3D models of your bore, visualize its dimensions, and simulate its behavior under different conditions. Some popular CAD software options for bore design include:

- Autodesk Fusion 360

- SolidWorks

- CATIA

- Creo Parametric

Manufacturing and Simulation Tools

In addition to CAD software, you'll also need tools for manufacturing and simulating your bore design. These tools help you validate your design, optimize its performance, and ensure its manufacturability.

- Manufacturing Tools: Depending on your chosen manufacturing process, you may require specific tools such as CNC machines, lathes, or milling machines. These tools enable you to create precise bores with the desired dimensions and surface finish.

- Simulation Tools: Simulation software allows you to analyze the behavior of your bore design under various conditions. It helps you identify potential issues, optimize the design for improved performance, and ensure its reliability.

Step-by-Step Guide to Designing a Bore

Now that we've covered the basics and selected the necessary tools, let's dive into the step-by-step process of designing a bore.

Step 1: Define the Purpose and Requirements

The first step in bore design is to clearly define the purpose and requirements of your bore. Consider the following questions:

- What is the intended application of the bore? (e.g., engine, firearm, drilling equipment)

- What are the specific requirements in terms of diameter, depth, and surface finish?

- What materials are suitable for the application, and what are their properties?

Step 2: Create a 3D Model

Using your chosen CAD software, create a detailed 3D model of the bore. This model should accurately represent the dimensions, shape, and features of the bore. Ensure that you pay attention to the following aspects:

- Diameter and depth measurements

- Surface finish requirements

- Material properties and specifications

Step 3: Simulate and Analyze

Once you have your 3D model, it's time to simulate and analyze its behavior. Utilize simulation software to subject your bore design to various conditions and scenarios. This step helps you identify potential issues, such as stress concentrations, material deformation, or thermal effects.

Step 4: Optimize and Refine

Based on the simulation results, optimize and refine your bore design. Make adjustments to the dimensions, material selection, or manufacturing process to improve the performance and reliability of your bore. Consider the following aspects during this step:

- Reducing stress concentrations

- Minimizing material deformation

- Optimizing thermal management

- Ensuring manufacturability

Step 5: Manufacture and Test

With your optimized design in hand, it's time to manufacture the bore. Use the appropriate manufacturing tools and techniques to create a physical prototype. Test the prototype under real-world conditions to validate its performance and ensure it meets the defined requirements.

Advanced Techniques for Bore Design

Once you've mastered the basics of bore design, you can explore advanced techniques to further enhance the performance and functionality of your bores.

Surface Treatments and Coatings

Surface treatments and coatings can significantly improve the performance and longevity of your bores. Consider the following options:

- Hard Chrome Plating: This process involves depositing a layer of chromium onto the bore's surface, enhancing its hardness and corrosion resistance.

- Nickel-Boron Coatings: Nickel-boron coatings provide excellent wear resistance and low friction, making them ideal for high-performance applications.

- Ceramic Coatings: Ceramic coatings offer exceptional heat resistance and can improve the overall durability of your bore.

Precision Manufacturing Techniques

Precision manufacturing techniques allow you to create bores with extremely tight tolerances and exceptional surface finishes. Some popular techniques include:

- Electrical Discharge Machining (EDM): EDM uses electrical discharges to remove material, resulting in highly precise and accurate bores.

- Honing: Honing is a finishing process that creates a smooth and uniform surface finish, reducing friction and improving performance.

- Grinding: Grinding is a versatile technique used to create bores with precise dimensions and smooth surfaces.

Quality Control and Inspection

Quality control and inspection are crucial aspects of bore design. They ensure that your bores meet the required specifications and perform as expected. Here are some key considerations:

Dimensional Inspection

Inspect the dimensions of your bores using precision measuring tools such as micrometers, calipers, or coordinate measuring machines (CMMs). Ensure that the diameter, depth, and other critical dimensions are within the specified tolerances.

Surface Finish Inspection

Evaluate the surface finish of your bores using surface roughness testers or profilometers. Compare the measured surface finish with the desired specifications to ensure it meets the required standards.

Material Testing

Conduct material testing to verify the properties and performance of the chosen materials. This includes tests for hardness, tensile strength, corrosion resistance, and other relevant properties.

Troubleshooting Common Bore Design Issues

Despite your best efforts, you may encounter common issues during the bore design process. Here are some troubleshooting tips to help you overcome these challenges:

Issue: Excessive Wear and Tear

If your bore is experiencing excessive wear and tear, consider the following solutions:

- Evaluate the material selection and consider using harder or more wear-resistant materials.

- Improve the surface finish of the bore to reduce friction and wear.

- Explore the use of lubricants or coatings to enhance wear resistance.

Issue: Poor Performance

If your bore is not performing as expected, try the following:

- Review the design and optimize it for improved performance. Consider factors such as material selection, surface finish, and manufacturing techniques.

- Conduct thorough testing and simulations to identify and address any design flaws.

- Seek expert advice or consult with experienced engineers to gain insights and solutions.

Issue: Manufacturing Challenges

Manufacturing bores can be complex, and you may encounter challenges along the way. Here are some tips to overcome manufacturing issues:

- Collaborate with experienced manufacturers who have a proven track record in bore production.

- Provide detailed specifications and drawings to ensure accurate manufacturing.

- Consider alternative manufacturing techniques or materials if traditional methods are not suitable.

Conclusion

Designing a bore requires a combination of expertise, precision, and attention to detail. By following this comprehensive guide, you'll be well-equipped to create bores that meet your specific needs and deliver optimal performance. Remember to select the right tools, understand the basics, and continuously refine and optimize your designs. With dedication and a deep understanding of bore design principles, you can achieve exceptional results.

FAQ

What is the importance of surface finish in bore design?

+Surface finish plays a crucial role in bore design as it directly affects the performance and longevity of the bore. A smooth and well-finished surface reduces friction, minimizes wear, and improves the overall efficiency of the system.

Can I use 3D printing for bore design?

+While 3D printing has advanced significantly, it may not be suitable for all bore design applications. 3D printing is ideal for rapid prototyping and complex geometries, but it may not provide the precision and surface finish required for high-performance bores. Traditional manufacturing techniques are often preferred for critical applications.

How can I improve the durability of my bore design?

+To enhance the durability of your bore design, consider using high-quality materials with excellent wear resistance and corrosion protection. Additionally, apply surface treatments or coatings to further improve the bore’s durability and performance.