Screw Was Loose

Have you ever experienced that sinking feeling when you realize a screw is loose on your beloved bike? It's a common issue that many cyclists face, but fear not! In this blog post, we will guide you through the process of identifying and fixing a loose screw, ensuring your bike remains in tip-top shape. By following these simple steps, you can get back on the road with confidence and peace of mind.

Identifying the Loose Screw

The first step in fixing a loose screw is to locate and identify it. Take a close look at your bike and examine all the areas where screws are present. Pay attention to any parts that feel wobbly or unstable, as these could be signs of a loose screw.

Common areas to check include:

- Handlebars

- Stem

- Seat post

- Pedals

- Brake levers

- Gear shifters

- Derailleur

If you notice any of these components moving or feeling loose, it's time to take action.

Gathering the Necessary Tools

Before you begin tightening the loose screw, ensure you have the right tools at hand. Depending on the type of screw and its location, you may need the following:

- Screwdriver (flathead or Phillips, depending on the screw type)

- Allen keys (hex keys) for bolts and screws with hex sockets

- Torx driver for screws with a star-shaped socket

- Socket wrench for larger bolts

- Lubrication (e.g., bicycle-specific grease or oil)

It's essential to use the correct tool to avoid stripping the screw or damaging the threads.

Cleaning and Inspecting the Screw

Once you've identified and located the loose screw, it's crucial to clean and inspect it before tightening. Dirt, grime, and corrosion can affect the screw's performance and make it difficult to tighten properly.

- Use a soft cloth or brush to remove any dirt or debris from the screw and its surrounding area.

- Inspect the screw for any signs of damage, such as stripped threads or corrosion.

- If the screw is severely damaged, consider replacing it with a new one to ensure a secure fit.

Tightening the Screw

Now that your screw is clean and ready, it's time to tighten it. Follow these steps:

- Choose the appropriate tool for the screw type. For example, use a Phillips screwdriver for Phillips screws.

- Apply moderate pressure and turn the tool clockwise to tighten the screw.

- Be careful not to overtighten, as this can strip the screw or damage the threads.

- Check the screw's tightness by giving it a gentle tug. It should feel secure but not overly tight.

Additional Tips for Screw Maintenance

To prevent future loose screws and ensure the longevity of your bike, consider the following tips:

- Regularly inspect your bike for loose screws, especially after rides or when you notice any unusual vibrations.

- Apply a small amount of bicycle-specific grease or oil to the threads of screws and bolts to prevent corrosion and ensure smooth tightening.

- Keep your bike clean and well-maintained to minimize the risk of dirt and debris affecting screw tightness.

- Consider using threadlockers for critical screws, such as those on your headset or bottom bracket, to prevent them from coming loose during rides.

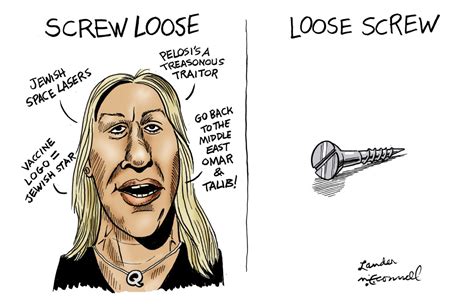

Visual Guide: Fixing a Loose Screw

For a visual representation of the steps involved in fixing a loose screw, check out this helpful diagram:

Remember, a loose screw can be a minor inconvenience or a safety hazard, so it's essential to address it promptly. By following these simple steps and maintaining your bike regularly, you can keep your ride smooth and enjoyable.

Conclusion

Dealing with a loose screw on your bike doesn't have to be a daunting task. By identifying the loose screw, gathering the right tools, cleaning and inspecting it, and tightening it properly, you can get your bike back in shape. Remember to regularly maintain your bike and address any loose screws promptly to ensure a safe and enjoyable riding experience. With these simple steps, you'll be back on the road in no time, confident in the knowledge that your bike is ready for any adventure.

Frequently Asked Questions

What if I can’t find the loose screw on my bike?

+

If you’re having trouble locating the loose screw, it might be hidden under components or in hard-to-reach areas. Take your time and examine your bike thoroughly, paying attention to any wobbly or unstable parts. If you still can’t find it, consider seeking help from a professional bike mechanic who can assist you in identifying and fixing the issue.

Can I use a different type of screw to replace a damaged one?

+

It’s generally not recommended to use a different type of screw as a replacement. Each screw on your bike is specifically designed for its intended purpose and location. Using an incorrect screw can lead to improper fit, potential damage to your bike, and even safety hazards. It’s best to replace a damaged screw with an identical one to ensure a secure and safe connection.

How often should I check for loose screws on my bike?

+

Regular maintenance is key to keeping your bike in top condition. It’s a good idea to check for loose screws at least once a month, especially if you ride frequently or in rough terrain. Additionally, always inspect your bike before and after long rides or when you notice any unusual noises or vibrations. By making screw checks a part of your routine, you can catch and address potential issues early on.

What should I do if I overtighten a screw and strip the threads?

+

If you accidentally overtighten a screw and strip the threads, it’s important to act promptly. First, try to remove the stripped screw using a specialized tool, such as an easy-out or a screw extractor. If that’s not possible, you may need to drill out the damaged screw and replace it with a new one. Seek guidance from a bike mechanic if you’re unsure about the process or if the damage is extensive.

Are there any tools I should avoid using for tightening screws on my bike?

+

Yes, it’s crucial to use the correct tool for the specific type of screw you’re tightening. Using the wrong tool, such as a flathead screwdriver for a Phillips screw, can result in stripped threads or damaged screws. Always refer to your bike’s manual or consult a bike mechanic to ensure you’re using the appropriate tools for each screw on your bike.